- Connections

- Sanding equipments

- Hoses

- Railways ball valves

- Pneumatic suspension valves

- Windscreen & wiping systems

- Other Railways Items

- Systems & components for industry

VEBEO COMPRESSION FITTINGS

1 complete range of compression fittings used for more than 50 years in :

- hard applications (vibrations, shocks, misalignment, ...)

- safety applications (braking, ...),

- applications with low temperatures -50 ° C.

- in accordance to ISO 1179-2

Vebeo reliability has largely been recognized in the international railway sector.

The mounting easiness and time savings are important assets in its use.

Respect for Vebeo fitting mounting instructions ensures the smooth operation and longevity of the installation.

PUSH-IN FITTING PNEUCLIP

This fitting allows :

- Instant automatic connection by simply introducing rigid polyamid or polyurethan tube OD 4 to 14 mm

- disconnection by simply pressing the release collar.

Pneuclip fittings offer 2 ranges giving perfect tightness on the low pressure because of their original technology networks :

- Push-in fitting.

- Push-in fitting with "function" :

- flow limiters,

- valves controlled locking function,

- circuit selectors.

When in action, this product lays sand between the wheels of the train and the track. This increases the grip when the train sets off as well in the case of emergency braking.

The sand blaster has a major role in guaranteeing the security for rolling stock and it’s passengers

Introducing innovative sand ejector - USB (Universal Sand Blaster)

Compact size. Light-weight (1kg for aluminium version).

Low risks of clogging.

Adaptable to all existing sanding systems.

Allows change of sand whilst in operation.

No wear parts: Minimal maintenance costs.

Mechanical adjustment of outlet flow possible directly on blaster.

FBO offers also other 5 types of ejectors sand for all railway rolling vehicles :

- Standard gravitational type (approved by SNCF - MTSL 2 / 97-00478)

- Multiple type

- Monobloc type

- Compact type

- DEM type

with :

with :

- Unclogging function.

- 45° or 90° position.

- Sand flow according to customer demand.

- Working pressure 4 to 9 bars.

- Used on High Speed train (HST).

- Association with heater for very low temperature.

FBO offers complete solutions for sanding including made-to-measure design, production of stainless steel sandboxes following standard EN 15085-2 and supply of adapted compressors.

Beyond the classic mechanical options, FBO «intelligent» options favouring preventive maintenance such as sand level measurement, diagnostic functions, flow rate depending on the speed of the train

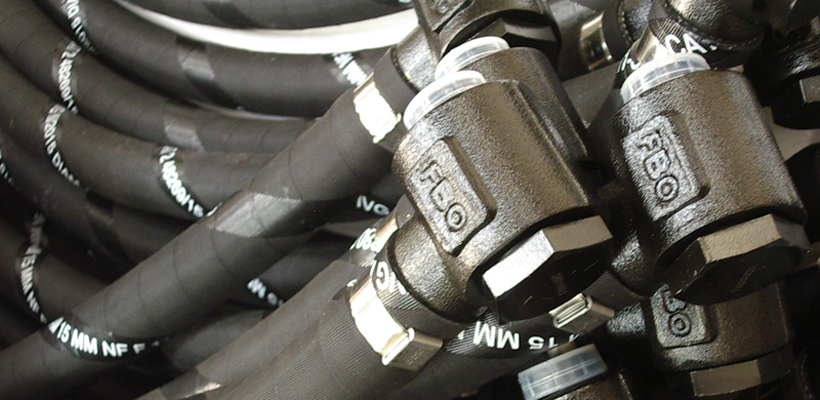

FBO offer tailor made flexible solutions for multiple applications for the railway rolling stock market:

- Connection brakes - bogies

- Connection passenger cars - bogies

- Sandblasting

- Compressors

- Drain tanks, ...

- Vebeo fittings Union, male, adapter, female, equal, banjo.

- Swivel nuts according to NFF 11-070 standards, DIN 20078, BS 5200, DIN 43210 24 ° or NFL.

- The connection is made by clamp, setting or welding.

- PVC spiral sleeves

- stainless steel braids.

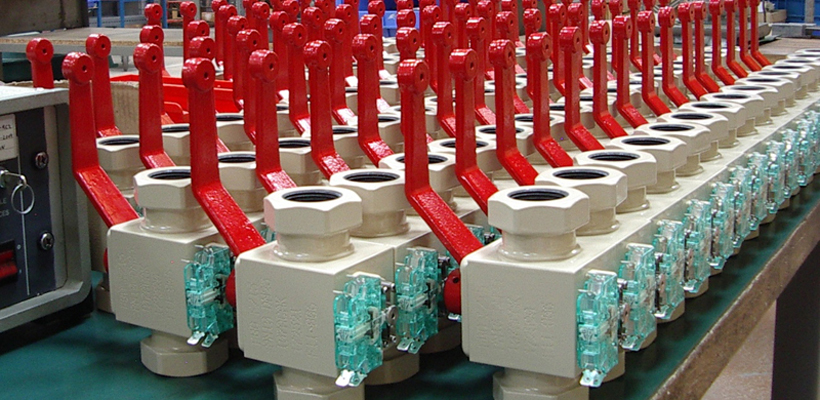

FBO offers for railway rolling vehicles :

- 1 isolating valve line ø 8 to 40mm for compressed air systems.

- 1 stop valves line ø 8 to 25mm pipe and main pipe homologated by SNCF.

Isolating valves exhibit the following features :

- Screw according to NF F 11-806.

- Flange according to standard STM 806

with possible options : safety lock, electric contacts, paint, gaskets for various temperatures or fluids.

The stop valves DN25 have to be screwed on pipes according to EN 14601 and NF UIC 542 with possible options: painting, sensitive notched handle, thick cataphoresis painting

DN65 drain valve is used for passenger cars equipped with recycled toilet holding tanks.

It is designed :

- to meet the specific requirements of the environmental field.

- to withstand bactericidal and descaling products.

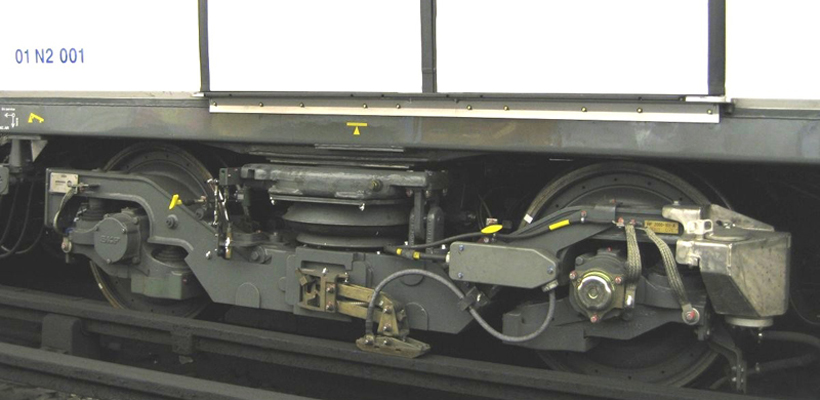

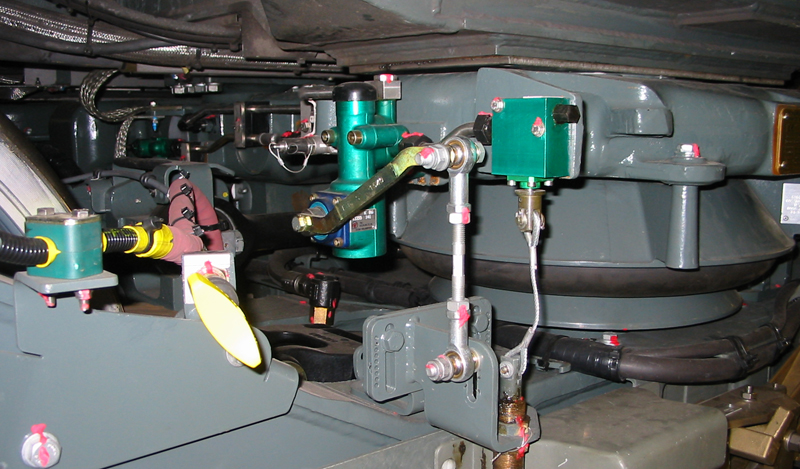

PNEUMATIC SUSPENSION VALVES

FBO is offering:

- suspension valves for HST or intercity trains and subways for travelers’ comfort

- integration of these products in plates or tube circuits for a complete air suspension function.

The leveling valve is intended to equip the air-spring suspensions with the functions:

- to maintain the bogie-body distance regardless of the load distribution

- to control the inflation & deflation of the suspension cushions

- with vertical or horizontal mounting on the bogie or on the car-body.

- with enhanced corrosion (600 hours salt-spray).

- Optional mounting of a check valve on air supply.

The differential valves ensures the level of the vehicle in the event of major leak in an air-spring.

It connects the two suspension cushions and ensures the angle of the vehicle in the event of a leak. If a pressure difference is detected between the right and left cushions, the valve will ensure that the pressure difference is no more than a certain amount of bars (standard: 1,25 bars). Can be modified upon request.

The safety valve (or discharge valve) ensures fast draining of air-cushions in case of failure for the case where the distance from car-body to bogie exceeds the determined threshold.

Connected to the bogie frame, the safety valve consists of two chambers isolated by a valve. The valve is returned by a spring.

Advantages of FBO valves: Complies with EN 45545; Low temperature option (-40°C); No preparation required; Quick setting.

- for mounting on the compressed air line for the pneumatic spring suspension

- to avoid significant pressure losses

- for periodic cleaning without dismantling the piping.

FBO is experienced for many years in the constraints of equipment for rail windscreen wiping & washing systems (WWWS) :

- Technical valuation and complete function

- Tailor-made systems upon request

- Reliability study (RAMS)

- Technical support

- After-sales service.

Every wiping system product has been especially developed for the railway rolling stock. The research of the proper materials, thermal treatments and seals enable the complete system to reach a high level of reliability. FBO systems allows to avoid safety related issues and cases when train doesn’t operate in the severe weather.

FBO is selected for the function windscreen wiping & washing systems by many railway operators such as the national railways: French, English, Belgian, Dutch, Korean, Indian and others.

Electric windscreen wiping systems

An electronic motor card with software has been developed allowing:

- Synchronization of up to 3 systems

- Automatic activation of wipers when using washing system

- Once washing is finished wiper will continue to function in order to evacuate water on screen

- “Safety mode” in case of system failure ensuring a slow speed (fixed at 25 RPM), parking position & water pump activation.

Our diagnostics electronic card allows:

- Analysis of wear of pump & motor

- “Overload” analysis on motors and pump

- Dry screen detection (allows to preserve blades)

Advantages:

- Easily adaptable to all types of railway rolling stock

- Adjustable speeds and intermittent speeds

- Allows predictive maintenance

- Adjustable wiping angles

Pneumatic windscreen wiping systems

Operates with pneumatic or electro-pneumatic motors for a nominal adapted torque.

Angular or parallel scanning with the integrated pantograph system in tubular arm.

Adjustable sweeping speed.

Intermittent sequences and parking position: the choice is yours.

Advantages:

- Perfect reliability at high speeds

- Synchronization is possible for multiple systems

- Large number of different lengths of arms and blades

- Adjustable speeds

HORN CONTROL VALVE

The horn control valve meets the requirements of SNCF Technical Specification No. 4MCS0826 and is mounted on the main panel of the driving cab.

A pneumatic or electro complete range for all rail vehicle :

- With 1 or 2 switches or without,

- With joystick or button.

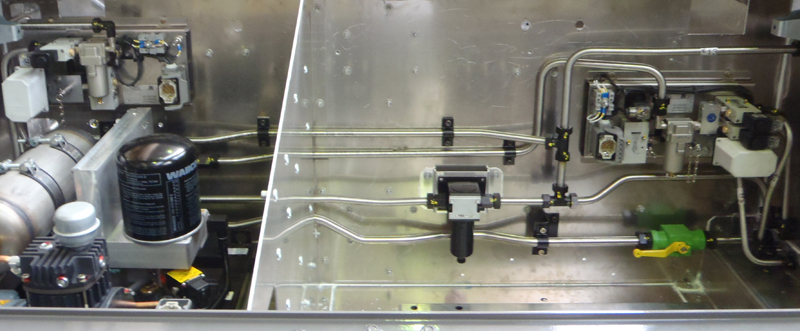

KIT FORM

FBO through a complete service for automation, carried out the study, analysis and implementation of kit forms :

- Pipe following requirements of the Specifications : material, function, etc ...

- Implementation

- Definition of the required components: fittings, valves, hoses, etc ...

- Respect for very low temperatures.

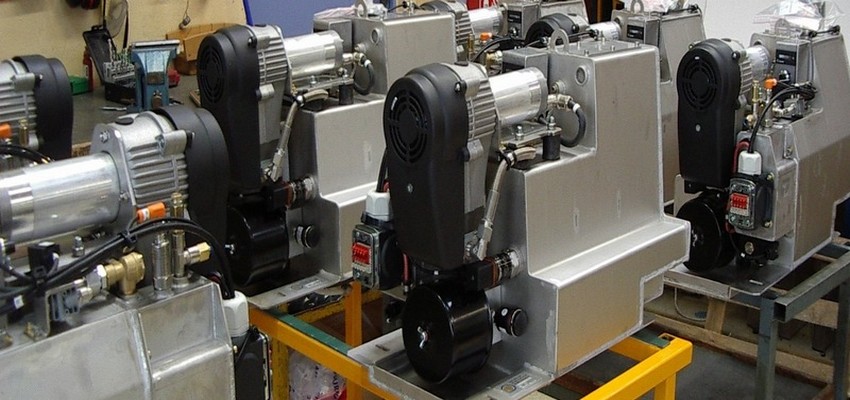

CONTROL SYSTEMS

For quick and easy maintenance FBO performs pneumatic functions grouped in the same control system for example :

- control access doors, inside doors, gangway doors in trains,

- toilet control

- suspension control,

- wiper control,

- seats control,

- air conditioning control.

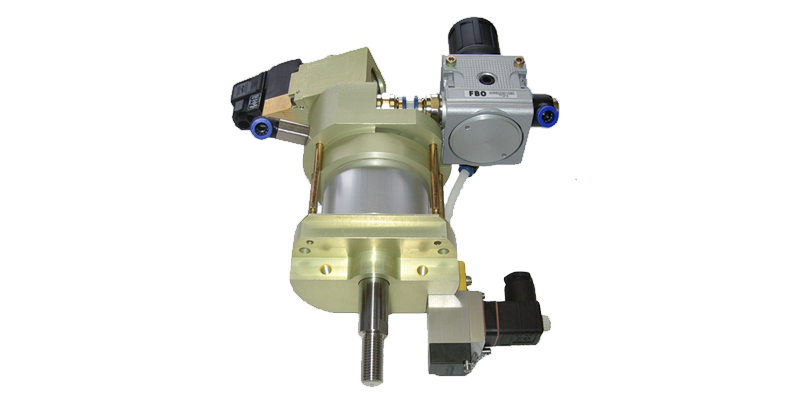

PNEUMATIC RAILWAYS CYLINDERS

For over 45 years FBO has a perfect experience in design and development of embedded pneumatic cylinders on passenger rail vehicles (trains, trams, subways,...).

The use of the cylinder is primarily on :

- doors

- pantographs

- High Speed Trains coupling.

The pneumatic operation can be completed by a mechanical lock even without compressed air.

Footrest

PNEUMATIC CYLINDERS

FBO is offering a large range of cylinders in compliance with standards :

- ISO 6432/6431 - NFE 49003

- CNOMO June 07 02/03 - AFNOR 49 001/002

wide-spread in industry and especially in the food industry with the series :

- PX stainless steel cylinders designed for their resistance to corrosion and cleaning.

PNEUMATIC & ELECTRO-PNEUMATIC VALVES

FBO offers 2 lines of distributors 3/2, 5/2 & 5/3 :

- Valves ISO 5599/1 sizes 1, 2 & 3.

- Direct connection valves (Mindman series) 1/8, ¼, 3/8, ½ withpneumatic or electric controland manual lever.

FBO also provides a variety of sensors in pneumatic or manual mechanical action :

- Sensors and manual control button.

- Mechanically controlled sensors.

- Micro-sensors.

- Foot-valves.

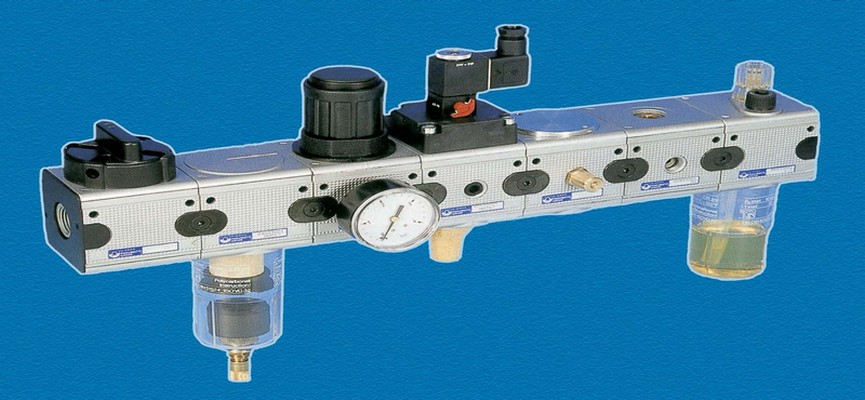

PRESSURE REGULATORS, FILTERS AND LUBRIFICATORS

FBO has a modular equipment line from 1/8 to 1" allowing any combination during the processing of compressed air :

- filters.

- Pressure regulators.

- lubricators.

- Filter-Regulators.

- Isolating valves.

- Isolating switch-off pressure.

- Progressive starters.

- bypass blocks.

- gauges.